Plastic Recycling Innovation

In addition to on-site renewable energy infrastructure, Pure energy is actively engaged in promoting effective circular economy solutions.

By introducing efficient plastic recycling technology to businesses, we are able to utilise the produced gas by-product to power on-site plastic recycling facilities.

“

Almost 10 billion tonnes of various plastics have been made globally since the 1950s

Almost 10 billion tonnes of various plastics have been made globally since the 1950s – two-thirds of that in the two decades after 2000. Packaging and shopping bags amassed in daily life are not recycled and instead end up in landfills or incinerators.

In the EU, around 30 million tonnes of plastic waste are generated every year. From yoghurt pots and milk cartons to shampoo bottles and toothpaste tubes, each European citizen produces an average of 35kg of plastic packaging waste per year.

Investigate Europe research describes in detail Europe’s problem with plastics production and usage. Their investigation exposes a number of failings in EU’s efforts to achieve a circular economy and details how unchecked production and use is creating a plastic waste crisis across the continent.

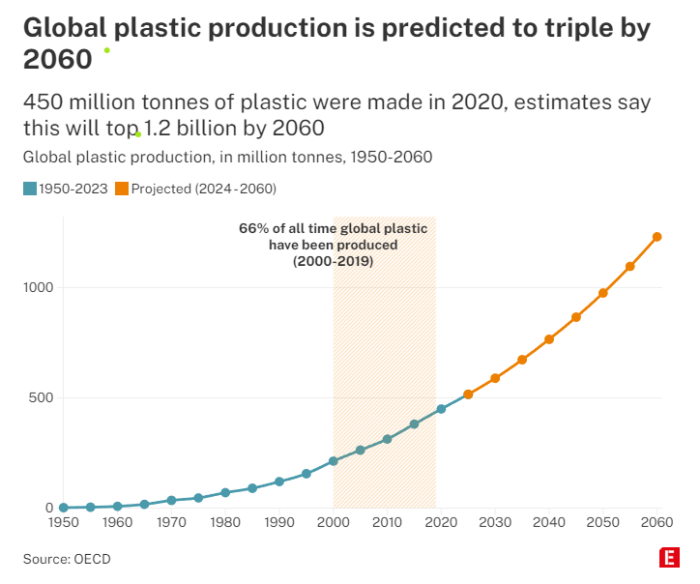

According to the OECD, based on current plastic consumption, annual plastics production levels is expected to triple by 2060, see figure one below.

United States researchers currently predict plastic production and disposal will be responsible for around 15 per cent of global CO2 emissions by 2050, accelerating an already unprecedented environmental catastrophe; European and US researchers have also recently calculated that 11 million tonnes of plastic waste flow into the oceans each and every year. By 2030, it could be twice as much – unless effective action is taken now to prevent this environmental harm.

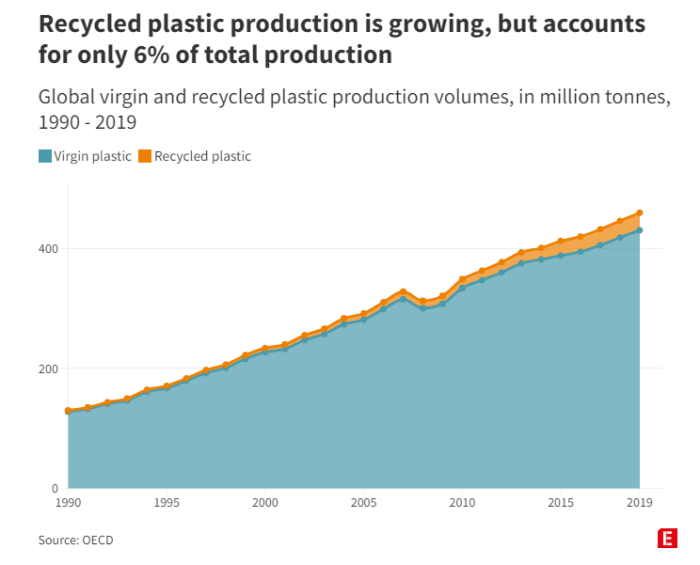

Europe is above the world average in the proportion of recycled plastic produced, but even here it remains around 10 per cent. Globally, the rate is much worse at six per cent. It is also estimated that at best 40 per cent of Europe’s plastic waste is recycled. Lack of recycling facilities is paired with an ever-increasing demand for new plastic products.

Packaging accounts for a significant proportion of plastic production (44 per cent globally, 40 per cent in the EU), with industry producing a high level of throwaway plastic. This production comes at a high environmental cost: by 2050, greenhouse gas emissions associated with plastic production, use and disposal could account for 15 per cent of allowed emissions.

This exponential growth is projected to continue unless we make changes soon.

While the amount of recycled plastic is increasing, see figure two, the amount of virgin plastic is ever increasing. We are also a long way from the EU’s recycling targets. For example, sorted plastic waste production in the EU has also doubled from 9.5 million tonnes in 2004 to 19 million tonnes in 2020.

Household waste is produced on a grand scale: being 180 million tonnes in 2004 and 203 million tonnes in 2020. A significant proportion of this is also plastic, mainly packaging. It is not surprising that only 32.5 per cent of plastic at best is recycled in Europe.

Various NGOs and studies have shown that much of the plastic sent for recycling ends up in landfills or is burned as data only captures plastics “sent or prepared for recycling.”

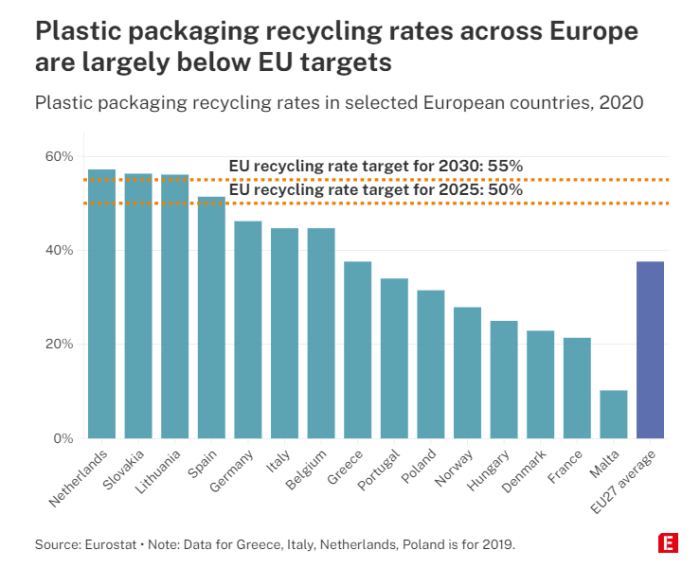

Recycling rates for household plastic packaging waste are slightly better, though in most countries far below the EU’s stated 2025 and 2030 targets. Plastic packaging waste generated in the EU increased by three million tonnes from 2012 to 2021, see figure three.

Widely used plastics in food packaging industries, polyolefins account for a large proportion of total plastic produced. These polymers are rarely recycled because their recycling requirements are generally more demanding. PERL’s preferred plastic recycling unit, WASTX™ Plastic technology processes PE, PP, HDPE, LDPE, LLDPE and PP + C polyolefins. Adhesions or similar contaminants are sorted out via the unit pre-treatment stage.

Tech-based solutions are being utilised to reduce plastic waste already polluting the environment and the ocean. In Croatia, for example, the port of Cres has deployed an automated floating seawater filtration device to pick up microplastics and other pollutants. Elsewhere, satellite imagery and advanced machine learning models are being used to detect and map plastic waste across 25 countries.

More broadly, gaps in the recycling sector must be improved to ensure more efficient management of waste resources and reduced risk of waste ending up in the environment. Similarly, embracing circular economic models – offering waste products a secondary lifespan through reuse, recycling, and upcycling – keeps resources in a closed loop system and can help avoid pollution. Platforms such as Loop, for instance, offer circular supply chain solutions and eliminate unnecessary waste from consumer goods packaging.

From a consumer goods lens, utilising more natural, degradable materials for products can also reduce plastic waste by tackling the start of the supply chain.

Governments have now taken the first steps to outline the rules of procedure for an international legally binding treaty on plastic pollution. The treaty will not be finalised until 2024, but is expected to have knock-on effects on major plastic-producer nations, consumer goods firms and chemical plastic manufacturers.

“

Plastic recycling to produce fuel will help address the issue of plastic waste while also generating a source of energy

Plastic recycling to produce fuel involves the conversion of plastic waste into various forms of energy, such a liquid fuels or gaseous fuels, through processes like pyrolysis and gasification. These processes will help address the issue of plastic waste while also generating a source of energy.

Pyrolysis is a thermal decomposition process that involves heating plastic waste in the absence of oxygen. This breaks down the plastic molecules into smaller hydrocarbon chains, leading to the production of a mixture of liquid and gaseous products. These products can be further refined into fuels, such as diesel, gasoline, or aviation fuel.

Gasification is like pyrolysis but typically involves a controlled amount of oxygen or steam. Plastic waste is heated to high temperatures and the resulting gas, known as syngas can be used as a fuel or as a feedstock for chemical processes.

It is important to note that while plastic to fuel recycling can offer a solution for some types of plastic waste, it is not a complete substitute for traditional recycling efforts and waste reduction strategies.

To maximize the environmental and economic benefits, a comprehensive approach that includes reduction, reuse, traditional recycling, and responsible waste management should be pursued alongside innovative plastic to fuel technologies.

To understand the optimum plastic waste recycling to energy technological solutions suitable for your business or community, contact Pure energy (REGen) Ltd via [email protected] or call +44 (0) 1382 657457.

Services (UK/International)

Technologies