Design Workshop

Location: The National Manufacturing Institute Scotland (NMIS) – 21st February, 2024

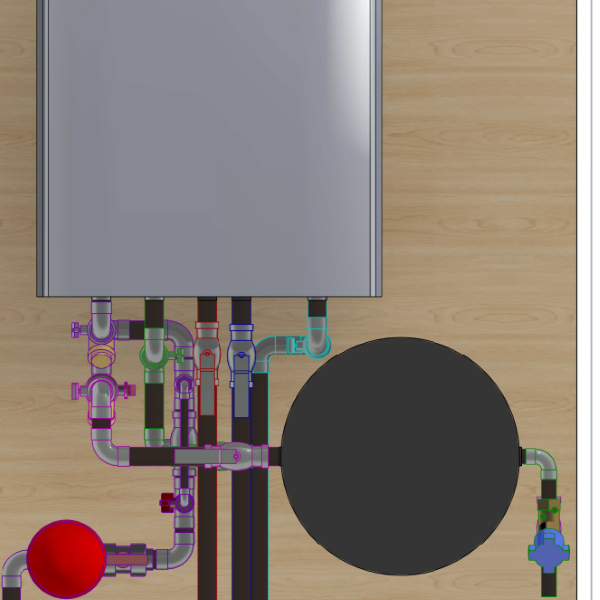

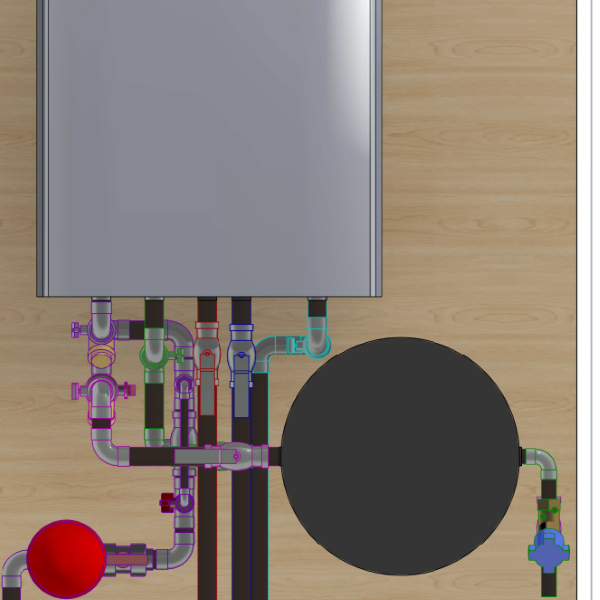

The “Energy Box” Heat Pump Assembly Design, is a first of its kind integrated design solution comprising heat pump and associated controls, all efficiently connected within an enclosure to provide efficient low carbon heating to domestic customers and available for both newbuild and retrofit installations.

“

The ‘energy box’ connects domestic properties to an outdoor ground source heating system in a simpler, more efficient way.

NMIS have been contracted by Pure energy to produce an initial design for manufacture concept for the ‘energy box’ product, based on the technical requirements considered during the Product Design Specification workshop held during Q4, 2023.

NMIS invited Pure energy to their Paisley Campus to participate in a follow-up interactive concept generation workshop to review their Design for Excellence (DFX) considerations of the ‘Energy Box’ product, with emphasis on efficient product assembly configuration, as a basis for further prototype development.

Pure energy and NMIS completed a “MIRO board” design and optimisation review, in order to complete initial product configuration selection, eliminating unsuitable materials and manufacturing processes and identifying opportunities by reviewing the existing ‘energy box’ CAD model design as initially created.

The various concept options discussed during the workshop will be further evaluated and where possible, standard parts and off-the-shelf components will be integrated within the product assembly to reduce both product manufacturing time and cost.

The primary output from the concept generation exercise will be an optimised assembly arrangement with associated structural stability essential during product supply to site and operational phases.

To complete this design development phase, Pure energy (REGen) Ltd received grant funding from Innovation UK.

To find out more about the ‘Energy Box’ project and how Pure energy (REGen) Ltd can assist your business or home to adopt low carbon heating solutions, contact us on +44 (0) 1382 657457 or email [email protected].

Services (UK/International)

Technologoies